Houston Epoxy Floor Coatings & Concrete Coating Specialists

Professional epoxy and polyaspartic floor coatings for garages and commercial spaces — installed with proper concrete prep, moisture control, and long-term durability in mind.

Proper prep • No shortcuts • Built for Houston conditions

Houston-Based Epoxy & Concrete Coating Specialists

Houston Floor Coatings is a Houston-based concrete coating company specializing in epoxy garage floors, polyaspartic floor systems, and commercial epoxy flooring. We serve homeowners and businesses across Houston and surrounding areas with systems designed for long-term performance – not rushed installs.

Our Core Services

Epoxy Floor Coatings

Epoxy floor coatings form the foundation of every garage and decorative floor system we install. A slower-curing epoxy base allows the material to penetrate the concrete surface, creating a stronger mechanical bond when the slab is properly prepared.

Decorative Epoxy Floors

Vinyl flake floors, metallic epoxy, and decorative quartz systems all fall under epoxy floor coatings. These finishes combine durability with visual customization for garages, showrooms, and interior spaces.

Deorative Concrete Finishes

We offer concrete overlays, stained concrete, and sealed concrete finishes for spaces where a natural or architectural look is preferred over a coated system.

Commercial Epoxy Flooring

Commercial epoxy flooring is designed for warehouses, shops, showrooms, and workspaces that require durability, chemical resistance, and minimal maintenance under heavy use.

Our Process

Most epoxy floor failures don’t happen because of the coating... they happen because of poor preparation.

Our process is built around preventing that.

01

Concrete Inspection & Moisture Evaluation

We evaluate slab condition, surface useage, and moisture issues before recommending any system.

02

Mechanical Diamond Grinding

We mechanically grind the concrete to open the pores and create the correct surface profile for adhesion. No acid washing. No shortcuts.

03

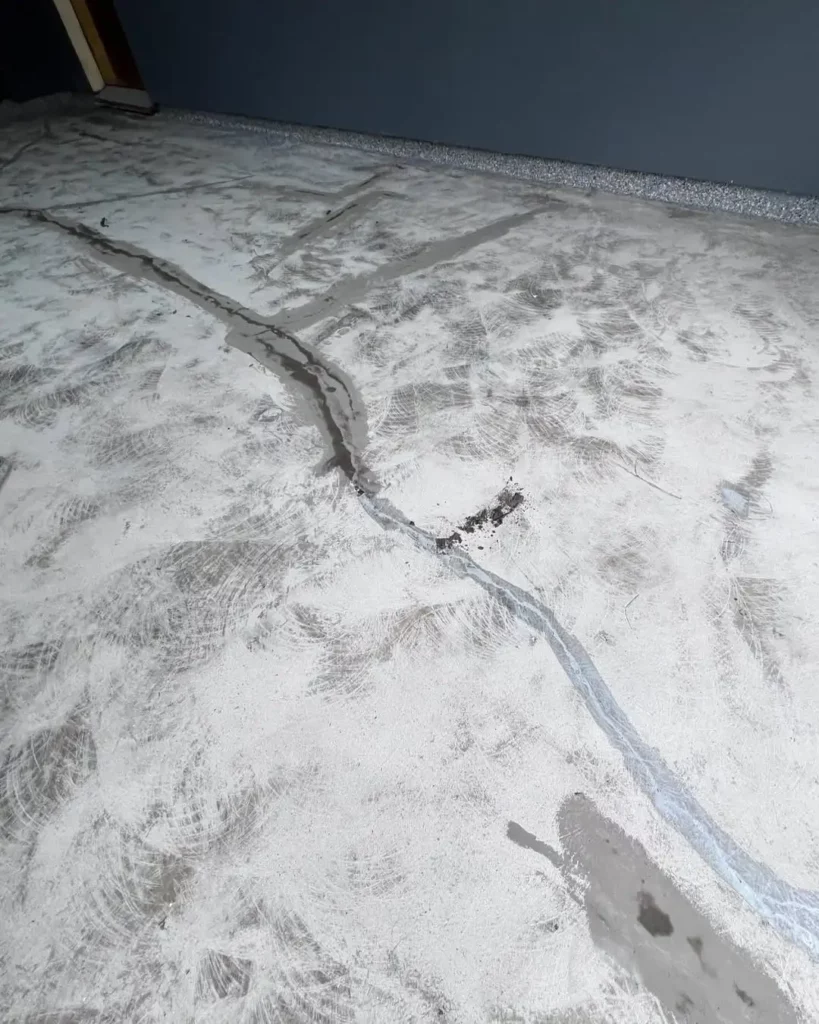

Crack & Surface Repair

Cracks, divots, and surface imperfections are repaired before coatings are applied to ensure a uniform finish.

04

Epoxy or Coating Installation

We apply the coating system selected for your space, usage, and environment — following manufacturer specifications.

05

Protective Topcoat & Cure Control

A durable topcoat is applied for wear resistance, slip control, and longevity, with cure times managed based on Houston’s climate.

Why Houston Floors Fail

Houston concrete presents unique challenges.

High humidity, moisture vapor, and rushed concrete pours… especially in newer homes, often leads to coating failures when installers skip proper prep.

We design our systems around Houston conditions, not national marketing claims.

Proudly Serving Greater Houston's Affluent Suburbs

Cypress, TX

As Cypress continues its rapid suburban growth, we provide durable, customizable epoxy garage floors and patio coatings built to handle both the regional humidity and active family life. We ensure a superior, long-lasting aesthetic for your expanding outdoor and indoor spaces.

Friendswood/Pearland, TX

We offer residential garage and exterior concrete solutions that address the common regional issue of soil movement. Our preparation methods are technically rigorous to ensure your coating resists shifting and provides a reliable, long-term bond.

Houston Heights, TX

For this historic and densely populated area, we focus on providing quick, low-VOC (Volatile Organic Compound) installations. We offer durable coatings for both historic residential homes and mixed-use commercial spaces, ensuring high quality with fast turnaround times.

Katy, TX

We serve active families and businesses near the Energy Corridor, specializing in quick-cure garage coatings that minimize disruption and maximize durability for high-demand residential traffic. Our coatings are built to last through the busy schedule of Katy ISD families.

Kingwood, TX

Our services here prioritize durable, long-lasting coatings for residential garages and outdoor spaces tailored to this wooded geography. We provide solutions designed to resist the area's moisture challenges while maintaining a beautiful finish.

League City, TX

Located close to the coast, League City slabs require special attention. Our expertise includes moisture mitigation and the installation of UV-stable pool deck solutions specifically designed to resist salt air, sun exposure, and persistent humidity.

Memorial/River Oaks, TX

We provide quick, clean installations focused on maximizing durability in older, high-value concrete slabs common to these established districts. Our solutions ensure a long-lasting, quality finish with minimal intrusion into high-value residential properties.

Sugar Land, TX

We address both high-end residential needs and critical commercial demands. Our services include heavy-duty floor repair and restoration for commercial and industrial facilities near major centers like the Smart Financial Center, focusing on verifiable slab integrity and heavy-duty topping specifications.

The Woodlands, TX

Our focus here is luxury and aesthetics. We deliver stunning high-end metallic and flake finishes ideal for master-planned communities like the "Livable Forest". We provide design consultations to ensure your garage or outdoor space perfectly complements your high-value home.

News & highlights

Stop Using Epoxy Paint on Garages: The Garage Floor Coatings That Hold Up

Epoxy Paint vs. 2-Part Epoxy Garage Floor Coatings: The Real Difference There are two different types of products people call “epoxy,” and that’s where most…

The real cost of a river rock floor

Read More ,

Watch This BEFORE Epoxying Your New Home

Read More ,

Epoxy Flake Floor Start to Finish | Orbit Flakes

Read More ,

Frequently Asked Questions

What is the typical cost per square foot for garage epoxy flooring in Houston?

Residential epoxy floor coating projects in Houston typically start around $4.50 per square foot, but the final cost can range up to $8 to $15 per square foot for high-end systems. Pricing is determined by the material specifications, such as using 100% solids epoxy and heavy-duty clear coats, and the size of the area. We provide transparent and clear pricing at time with our free estimates.

How long will my new floor coating last?

With proper care, a professionally installed epoxy/polyaspartic floor coating system is a permanent solution. Unlike DIY epoxy kits that can peel in 1-2 years, our system is designed to last a lifetime. That’s why we back every residential installation with a lifetime warranty against peeling, chipping, and delamination. It’s the last floor you’ll ever need.

Do you repair cracks and damage before coating?

Absolutely. A successful coating requires a sound substrate. As part of our standard process, we repair all visible cracks and pitting in the concrete after diamond grinding. We use a professional-grade mender that becomes part of the concrete itself, ensuring a smooth and seamless final surface.

Will the floor be slippery?

No. While the high-gloss finish looks smooth, our full-flake broadcast systems create a natural texture that provides more grip than bare concrete, especially when wet. For areas requiring extra traction like pool decks or walkways, we can incorporate an additional anti-slip aggregate into the top coat for maximum safety.

How long does the installation process take and when can I use my new floor?

A standard residential garage installation usually takes 1 to 2 days, depending on the necessary concrete preparation. Cure times vary, but you can typically resume foot traffic within 24 to 48 hours. We generally recommend waiting 5 to 7 days before driving a vehicle onto the new coating.